The application of colored YSZ nanomaterials in dentistry, synthesized through the advanced hydrothermal method, represents a significant stride towards achieving superior aesthetic and functional outcomes. The precise control offered by hydrothermal synthesis in conjunction with the inherent advantages of YSZ positions these nanomaterials as valuable assets in modern dental practices. This article aims to shed light on the innovative use of YSZ nanomaterials in dentistry, underlining their production process and the performance advantages they bring to the forefront of dental material science.

Innovative Applications and Advantages of YAG Products in Semiconductor Etching for LCD/LED Technology

In the rapid evolution of digital technology, the semiconductor industry plays a pivotal role in enhancing the performance of LCD and LED displays. Among the cutting-edge solutions, YAG (yttrium aluminum garnet) products have emerged as key contributors to semiconductor etching processes, revolutionizing the landscape of LCD and LED manufacturing.

Applications of Cerium Zirconium Mixed Oxide in Automotive Exhaust and Industrial Emission Control

Cerium Zirconium Mixed Oxide emerges as a crucial component in the realm of emission control, playing a significant role in reducing the environmental footprint of automotive exhaust and industrial processes. Its versatility, high catalytic activity, and compatibility with diverse applications position CZO as a key player in the pursuit of cleaner air and sustainable industrial practices.

YAG Y3Al5O12

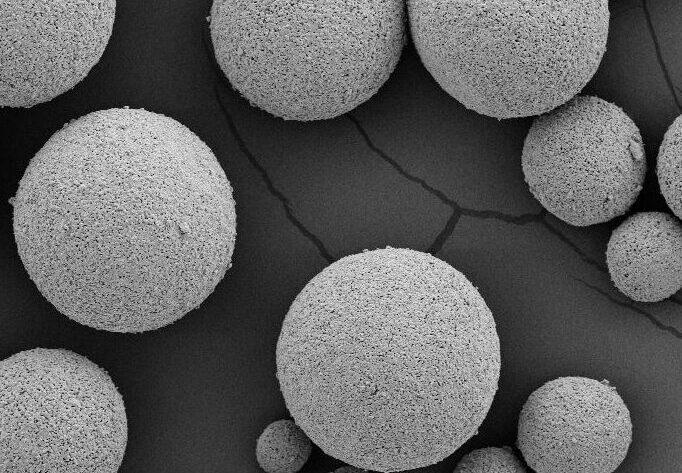

YAG, or yttrium aluminum garnet, is a common material used as a plasma spray coating due to its high melting point, thermal stability, and chemical inertness. The performance of YAG on plasma spray coating can be evaluated based on several factors, including its microstructure, phase composition, and mechanical properties.

CrownRe`s YSZ materials on TBCs field

YSZ, or yttria-stabilized zirconia, is a ceramic material that has been widely used in high-temperature applications, including as a coating material for environmental and thermal barrier coatings (EBC and TBC).

About CZO`s application

Cerium zirconium mixed oxide (CZO) is a composite mater…

PVD Y2O3 Yttrium oxide application

Physical vapor deposition (PVD) is a widely used technique in semiconductor integrated circuit (IC) manufacturing.

Sputter deposition is a physical vapor deposition (PVD) method of depositing thin films by sputtering, that is ejecting, material from a “target,” that is source, which then deposits onto a “substrate,” such as a silicon wafer. Resputtering is re-emission of the deposited material during the deposition process by ion or atom bombardment.

Sputter deposition is a physical vapor deposition (PVD) method of depositing thin films by sputtering, that is ejecting, material from a “target,” that is source, which then deposits onto a “substrate,” such as a silicon wafer. Resputtering is re-emission of the deposited material during the deposition process by ion or atom bombardment.