The study published in the Journal of Thermal Spray Technology explores the development of yttrium oxyfluoride (YOF) coatings using Y5O4F7 suspension deposited via Suspension Plasma Spraying (SPS) at atmospheric pressure. The research, conducted by Seungjun Lee, Jaehoo Lee, and Nong-Moon Hwang, aims to minimize Y2O3 formation and proposes the mechanism of SPS coating at atmospheric pressure. They analyzed coatings deposited from four suspensions with varying mass ratios containing Y5O4F7.

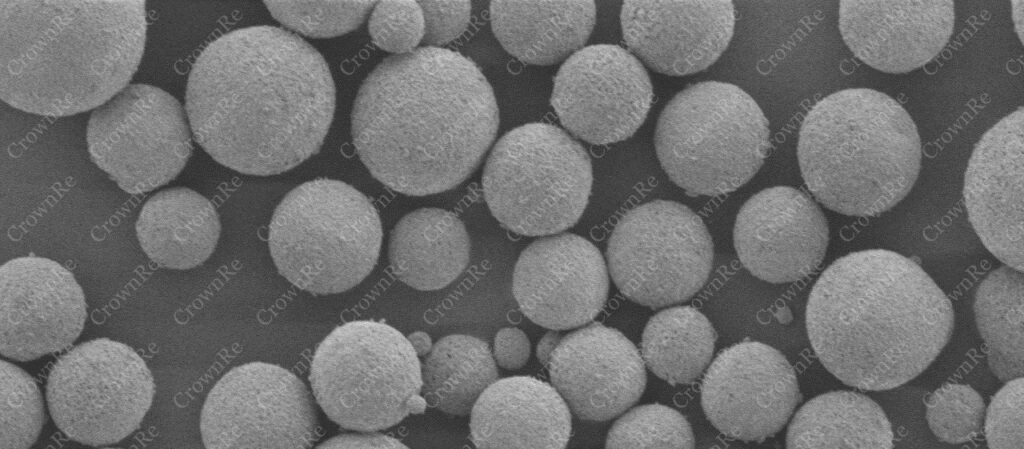

CrownRe produces Y5O4F7, a crucial material used in the study for its oxyfluoride properties. In the SPS process, Y5O4F7 suspension is heated to high temperatures in a plasma spraying gun and deposited onto substrates at atmospheric pressure, resulting in uniform and dense coatings. This research optimizes suspension composition and process parameters to achieve YOF coatings with excellent resistance to plasma environments.

YOF coatings find potential applications in protective coatings for high-temperature oxidation environments, such as aerospace and energy sectors, offering superior thermal stability, corrosion resistance, and mechanical properties to enhance material lifespan and performance reliability.

In summary, this study provides foundational experimental data and theoretical insights for the application of CrownRe’s Y5O4F7 in SPS processes, laying groundwork for the design and optimization of high-performance yttrium oxyfluoride coatings.