YSZ, or yttria-stabilized zirconia, is a ceramic material that has been widely used in high-temperature applications, including as a coating material for environmental and thermal barrier coatings (EBC and TBC).

Environmental barrier coatings (EBCs) are designed to protect turbine components, such as blades and vanes, from harsh environments that contain contaminants and corrosive substances. YSZ EBCs can provide a barrier against these harmful substances, reducing the rate of material degradation and extending the service life of the turbine components.

Thermal barrier coatings (TBCs) are used to reduce the temperature of the turbine components and protect them from the extreme temperatures generated by the combustion process. YSZ TBCs are an ideal material for this application due to their low thermal conductivity and high melting point. These properties allow YSZ TBCs to provide excellent thermal insulation, reducing the heat transferred from the combustion gases to the substrate material and minimizing the risk of material failure.

In addition to its excellent thermal and environmental protection properties, YSZ is also resistant to thermal shock, abrasion, and erosion, making it a durable coating material for high-temperature applications.

Overall, YSZ is a critical material in EBC and TBC applications, providing a high level of protection and durability to turbine components in a range of high-temperature environments. Ongoing research is focused on further improving the properties of YSZ coatings, such as their adhesion strength, to enable even more effective protection and longer service life of turbine components.

YbGd-YSZ, also known as ytterbium-gadolinium-doped yttria-stabilized zirconia, is a type of ceramic material that is commonly used in the manufacturing of turbine blades for gas turbine engines.

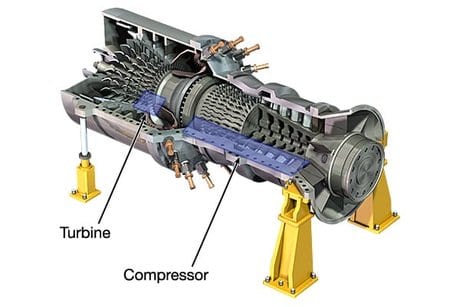

Gas turbines are widely used in aerospace and energy production, and turbine blades are critical components that need to withstand high temperatures, high stresses, and harsh environments. CrownRe`s YbGd-YSZ is an excellent candidate material for turbine blades due to its high thermal stability, excellent mechanical strength, and resistance to thermal shock and corrosion.

The addition of ytterbium and gadolinium to the yttria-stabilized zirconia (YSZ) matrix helps to enhance the thermal stability of the material by increasing the thermal conductivity and reducing thermal expansion. This makes it more resistant to thermal cycling and prevents cracking, which can occur due to the mismatch in thermal expansion between the ceramic blade and the metal turbine rotor.

In addition to its excellent thermal properties, CrownRe`s YbGd-YSZ also exhibits good mechanical strength, toughness, and wear resistance. This helps to ensure that the turbine blades can withstand the high centrifugal forces and stresses that are generated during operation.

Overall, CrownRe`s YbGd-YSZ is an ideal material for gas turbine blades due to its ability to withstand high temperatures, high stresses, and harsh environments, while also maintaining excellent mechanical properties.