CrownRe developed successfully Yttrium oxyfluoride Y5O4F7 in Solid phase synthesis process recently,which shows great XRD peak.

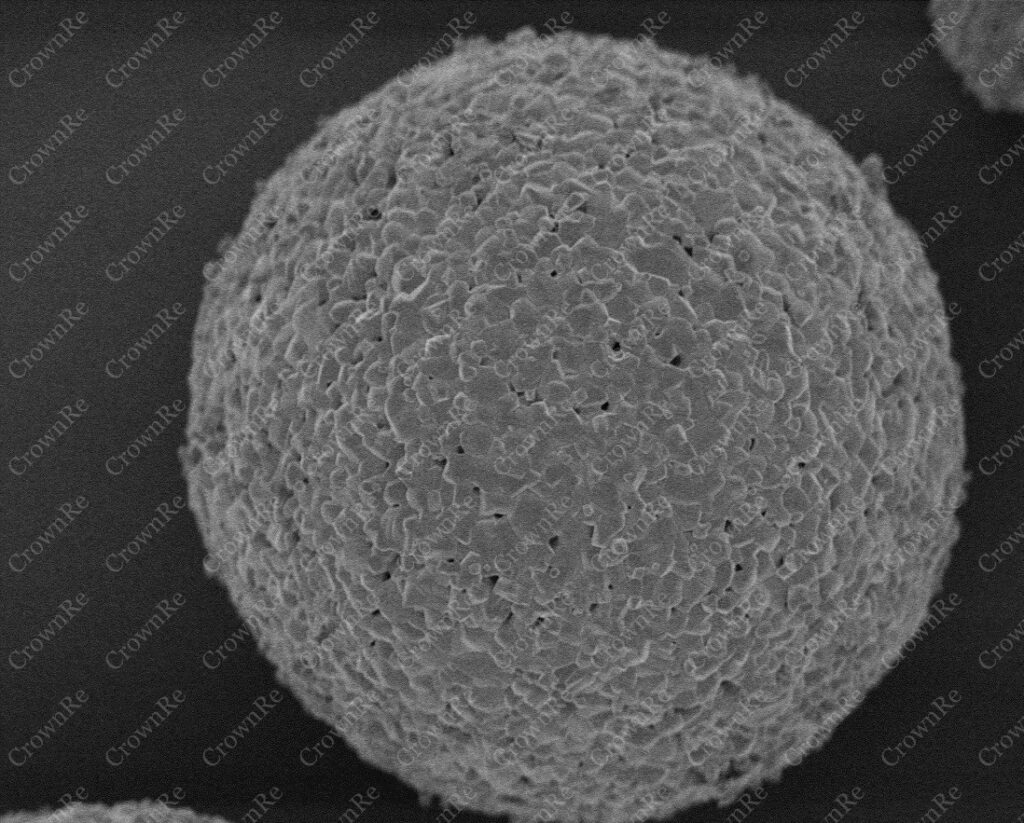

CrownRe produces Yttrium Oxyfluoride (YOF) compounds, including YO3, Y5O4F7, Y7O6F9, and YF3, using advanced chemical synthesis and solid-phase synthesis techniques. These products are characterized by high purity, low impurity content, and excellent sphericity.

Product Specifications: The Yttrium Oxyfluoride compounds manufactured by CrownRe meet stringent purity standards, ensuring minimal impurities that could affect performance in critical applications. They are available in various compositions including YO3, Y5O4F7, Y7O6F9, and YF3, tailored to specific technological requirements.

Production Techniques: CrownRe employs both chemical synthesis and solid-phase synthesis methods to produce Yttrium Oxyfluoride compounds. Chemical synthesis involves precise control over reaction conditions to achieve desired compositions and purity levels. Solid-phase synthesis ensures uniform particle size and high sphericity, crucial for applications requiring consistent performance.

Applications: These Yttrium Oxyfluoride compounds play a vital role in semiconductor manufacturing, particularly in the etching process of semiconductor chips. Key applications include:

- Etching Masks: YOF compounds are used in the production of etching masks for semiconductor chips. Their high purity and chemical stability enable precise etching patterns and control over semiconductor features, enhancing chip performance and reliability.

- Dielectric Materials: Yttrium Oxyfluorides find application as dielectric materials in semiconductor devices, providing insulation and enhancing electrical properties crucial for device performance.

- Optical Coatings: They are utilized in optical coatings where their optical transparency and stability under various environmental conditions are advantageous.

In summary, CrownRe’s Yttrium Oxyfluoride compounds are distinguished by their high purity, precise manufacturing processes, and tailored compositions suitable for demanding applications in semiconductor technology. They contribute to the advancement of semiconductor manufacturing by enabling precise etching processes and enhancing the performance of semiconductor devices.